Training

PROVIDING CUSTOMIZED TECHNICAL

AND OPERATOR TRAINING FOR PORT PERSONNEL

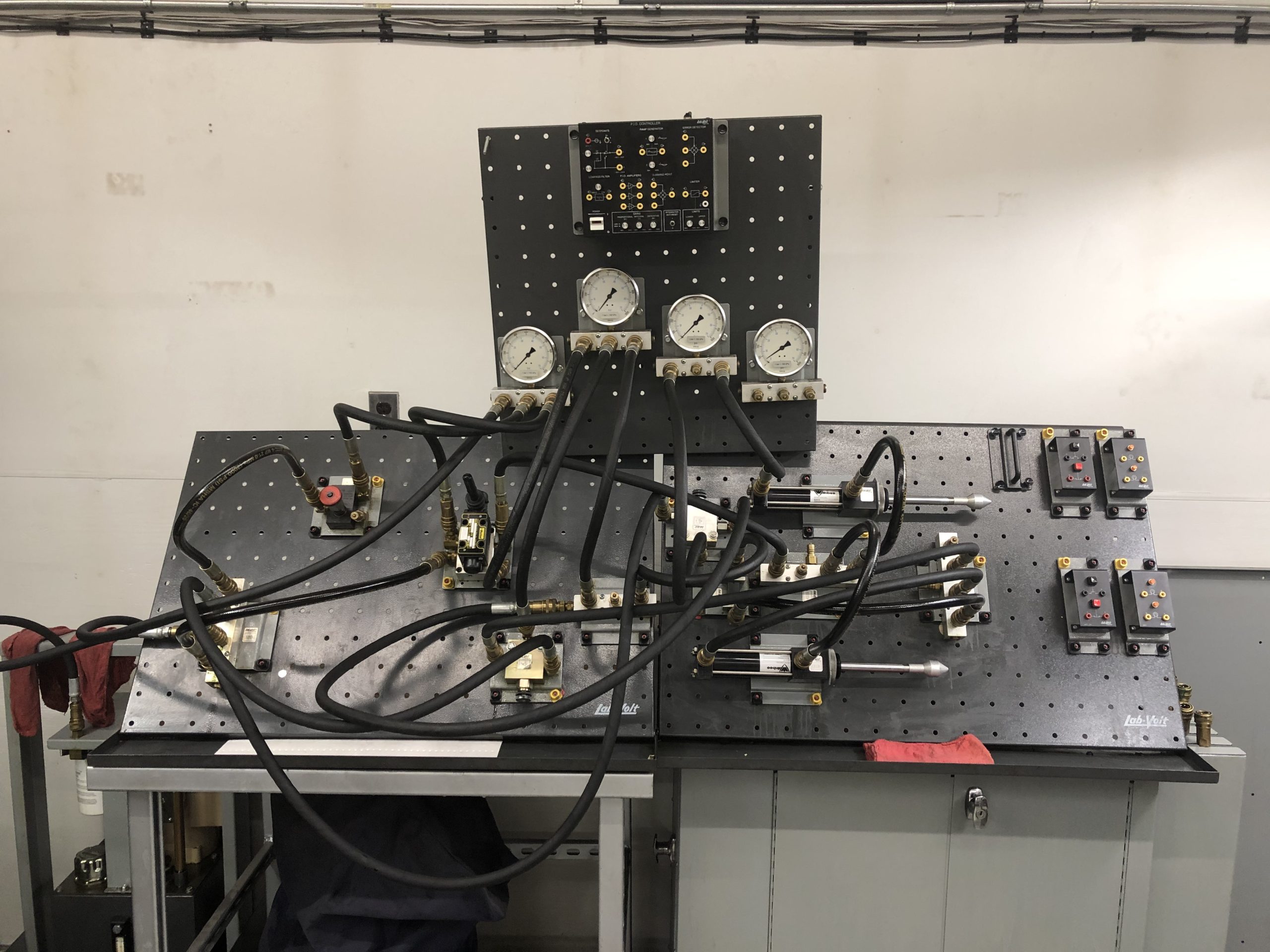

Technical Training

For over 20 years, Port Technical Services has conducted technical training tailored specifically for port mechanics. For out of town students, courses can be structured on a weekly basis at our 5,500 sq. ft. state of the art facility or we can come to you. The program offers training from the most basic maintenance fundamentals to the most advanced technology used in our industry.

Operator Training

PTS offers hands-on operator training on a wide variety of port-specific equipment. This training is typically performed at your facility and includes classroom and hands-on instruction on your equipment. Re-certification training is also performed. Instruction focus is on safety, equipment familiarity and skill improvement. Training documentation provided includes testing results, hands-on training results and certification paperwork. Our goal is to prepare port personnel for the challenges they face while operating the sophisticated port equipment of today and tomorrow. Our curriculum is aimed at improving safety and productivity that extends throughout your operation.

PTS offers hands-on operator training on a wide variety of port-specific equipment. This training is typically performed at your facility and includes classroom and hands-on instruction on your equipment. Re-certification training is also performed. Instruction focus is on safety, equipment familiarity and skill improvement. Training documentation provided includes testing results, hands-on training results and certification paperwork. Our goal is to prepare port personnel for the challenges they face while operating the sophisticated port equipment of today and tomorrow. Our curriculum is aimed at improving safety and productivity that extends throughout your operation.

Operator training is performed on the following equipment: